Gel Coated FRP GRP Composite Sandwich Panel Wall Panels Building Material Prefabricated House Roof Construction Material Insulated Panel Fiberglass

FRP XPS Sandwich Panel For Truck Floor And Exterior Wall Structure: FRP skin + XPS (extrude polystyrene foam) + FRP skin

Basic Info.

| Model NO. | ED |

| Advantage | Water Proof |

| Transport Package | Pallet |

| Specification | customized |

| Trademark | EDAO |

| Origin | China |

| HS Code | 7019909000 |

| Production Capacity | 40000sqm/Month |

Product Description

FRP XPS Sandwich Panel

For Truck Floor And Exterior Wall

Structure: FRP skin + XPS (extrude polystyrene foam) + FRP skin

Product description

Fiberglass Reinforced Plastic (FRP) sheet as surface panel at both sides, Polystyrene (XPS also called Extrusion board) as core. They are compounded from high pressure and vacuum,guaranteeing the strength and stability.

Overview

| Thickness: | 20mm-200mm,according to your application |

| Width: | up to 2.6m,standard size 1.8m |

| Length: | 2.4m standard, can be customer specific |

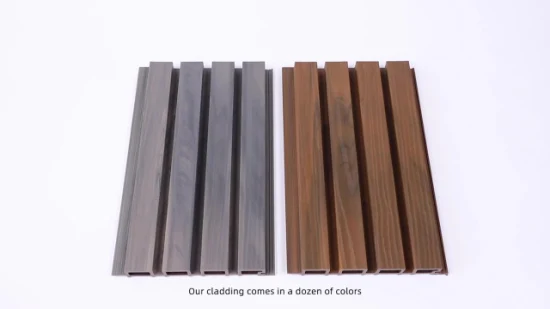

| Colors: | RAL No. |

| uv/weathering | Excellent protection |

| Bonding preparation | both side smooth or sanded; bonding with appropriate adhesives possible |

Typical Features:

1. Light-weight &high-intensity 2.fire resistant & insulation

3. anti-impact&scratch 4. Corrosion resistant

5. easy to clean & install 6. Anti-mildew, mould, moisture, resistant

7. Resilient to weathering and hail 8. Excellent thermal characteristics

Application:

Compartments and external walls of building and truck body.

Truck flooring panel

Ideal For

Transport Industry:

Trailers bodies, Caravan, Mobile home, Horse floats

Marine Industry:

Bulkheads and floors

Industrial and Commercial:

Lightweight but strong walls, thermal insulated feature walls

FRP XPS Sandwich Panels

Structure: FRP skin + XPS (extrude polystyrene foam) + FRP skin

Product description:

Fiberglass Reinforced Plastic (FRP) sheet as surface panel at both sides, Polystyrene (XPS also called Extrusion board) as core. They are compounded from high pressure and vacuum, guaranteeing the strength and stability.

Overview

Thickness: 12mm-150mm, according to your application

Width: up to 2600mm, standard size 1.22m

Length: 2440mm standard, can be customer specific

Colors: RAL-, scale or customer-specific shades

UV/weathering Excellent protection

Bonding preparation both side smooth or sanded;

Bonding with appropriate adhesives possible

Typical Features:

1. Light-weight &high-intensity

2. Fire resistant & insulation

3. Anti-impact&scratch

4. Corrosion resistant

5. Easy to clean & install

6. Anti-mildew, mould, moisture, resistant

7. Resilient to weathering and hail

8. Excellent thermal characteristics

Application:

Compartments and external walls of building and truck body.

Truck flooring panel

Partitions

Toilets, shower compartment

Contact:

LILY

mobile:00861513558670

Send to us