Heat Insulated Soundproof Fireproof EPS/Polystyrene/PU/PIR/PUR/Puf/Polyurethane/Rockwool/Glasswool Acoustic Sandwich Board Panel for Wall/Roof/Ceiling/Partition

EPS Sandwich Panel Metal Rockwool Sandwich PanelsAustralian Style Rockwool Sandwich Panel Series Metal Polyurethane/PU/P

Basic Info.

| Model NO. | Panel 1 |

| Certifiaction | ISO 14001, ISO 9001, FM, CE |

| Useful Life | 60 Years |

| Use | Wall/Roofing/Ceiling/Partition |

| Exterior Steel Thickness | 0.4mm-0.7mm |

| Discount | 3% Discount Above 3000m2 |

| Lead Time | 20 Days After Receiving Your Deposit |

| Shipping Container | 20gp, 40gp, 40hq 40ot |

| Advantage | Eco-Friendly, Waterproof , Fireproof, Soundproof |

| Thickness | 50mm/75mm/100mm/120mm/150mm/200mm |

| Width | 950mm/980mm/1000mm/1120mm/1150mm |

| Length | Customized, <11.8m |

| Steel Coating | PE/PVDF/SMP/HDP |

| Core Density | 10/12/14/16/18/20/40/80/100/120 Kg/M3 |

| Color | Customized |

| Interior Steel Thickness | 0.4mm-0.6mm |

| Transport Package | Standard Marine Packing |

| Specification | Customized as your need |

| Trademark | Jedha |

| Origin | China |

| HS Code | 73089000 |

| Production Capacity | 3000 Meters/Day |

Product Description

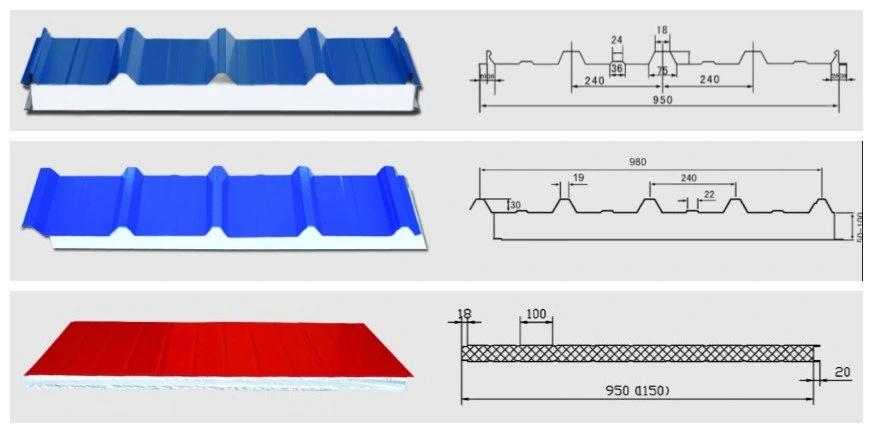

EPS Sandwich Panel

| Thickness | 50/75/100/120/150(mm) |

| Effective width | 950, 980, 1150(mm) |

| Length | According to customer' s request, less than 11.8m. |

| Materials | Polystyrene foam board, Color steel tile |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: Polystyrene foam board | |

| EPS density | 10/12/14/15/16/18/20 kg/m³ |

| Conventional color | White, sea blue, red etc. |

| Lifetime | More than 60 years |

| Performance | Light weight, heat insulation, water resistant, green and environmental |

| Usage | Roof, Wall, Ceiling, Partition |

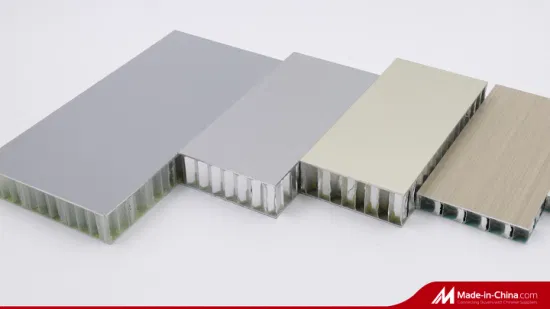

Metal Rockwool Sandwich PanelsAustralian Style Rockwool Sandwich Panel Series

| Thickness | 50/75/100/120/150/200(mm) |

| Effective width | 950, 980, 1100, 1150(mm) |

| Length | According to customer' s request, less than 11.8m. |

| Materials | Polystyrene foam board, Color steel sheet |

| Structure | Upper and lower layer: 0.4mm-0.8mm Color steel sheet |

| Middle: Polystyrene foam board | |

| EPS density | 60/80/100/120 kg/m³ |

| Conventional color | White, sea blue, red etc. |

| Lifetime | More than 60 years |

| Performance | Light weight, heat insulation, water resistant, green and environmental |

| Usage | Roof, Wall, Ceiling, Partition |

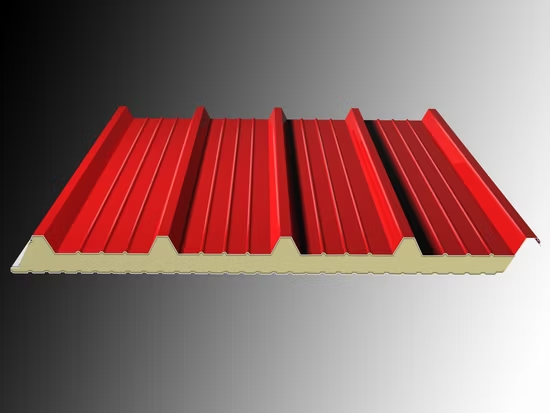

Metal Polyurethane/PU/PIR/PUR/PUF Sandwich Panels

1. Roofing panel2. Wall panel3.Cold room panel Performance

Packing&Delivery

Project CasesFAQ

Q1: Do you offer guiding service for installation on site overseas?

A: Yes. We do. We will give detailed installation drawings and video for free. And if you need, we can send guide engineers as installation director even a working team to your construction site. Q2: How can I get your quick quotation on my project?

A: You can chat with us at anytime via email or phone to offer us your detail information or you can just leave your message on our website. We will give you the best quotation ASAP. Q3: What's the procedure of trading?

A: Design drawing →Confirm drawing→Quotation→PI→ConfirmPI→Arrange 30% deposit→Manufacture→ QCinspect→ Paybalance→Shipping.Q4: What is the biggest advantage of your product?

A: We use high-quality raw materials, strictly control the quality of production. We improve our product performance by improving our technology. These make our products more beautiful and have a longer life, lower cost of use.

Send to us